You get a dedicated consultant who will identify your company’s safety and health risks and deliver continued oversight, guidance, and training to keep your employees safe and protect your business from fines and litigation. You’ll also receive a custom safety plan as your roadmap for continuing improvement, along with a suite of J. J. Keller resources to help you manage risks more effectively. The result is a high-impact program that supports your operation at a fraction of the cost of a full-time employee.

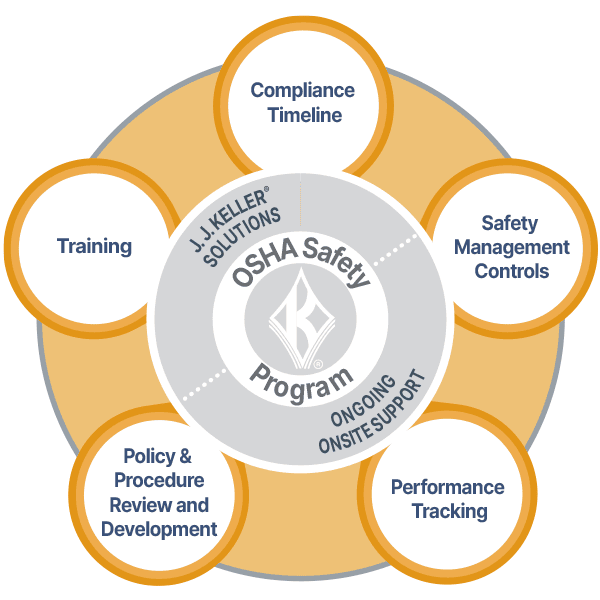

OSHA Compliance Program areas of focus include: